Our Facilities

We have two state-of-the-art facilities located in Michigan, equipped with the latest technology and staffed by highly skilled professionals.

Auburn Hills Plant

> 100,000

Components placed per hour

Facility Exterior

Production Floor

Facility Overview

Our Auburn Hills plant is a high-volume SMT production facility engineered for scalability and performance. It is equipped with multiple SMT lines supporting boards up to 48 inches, selective solder capabilities for through-hole components, and a modular floorplan that allows for flexible manufacturing and future expansion.

Key Capabilities

High-Volume SMT Production

Selective Soldering for Through-Hole Components

Large-Format Board Handling (up to 48”)

Flexible Manufacturing Layout

Expansion-Ready Infrastructure

Madison Heights Plant

3

SMT Lines

Facility Exterior

Production Floor

Facility Overview

Our Madison Heights plant is a highly flexible, hi-mix PCB assembly plant tailored for both low and production volumes. It supports a variety of board materials—including FR4, metal core, rigid, and flex—and delivers specialized solutions for ECUs, LED lighting, and instrumentation. With a focus on precision and quality, this facility also provides conformal coating and other finishing services.

Key Capabilities

Hi-Mix PCB Assembly

Low to Production Volume Builds

Support for FR4, Metal Core, Rigid & Flex Boards

ECU, LED, and Instrumentation Specialization

Conformal Coating & Finishing Services

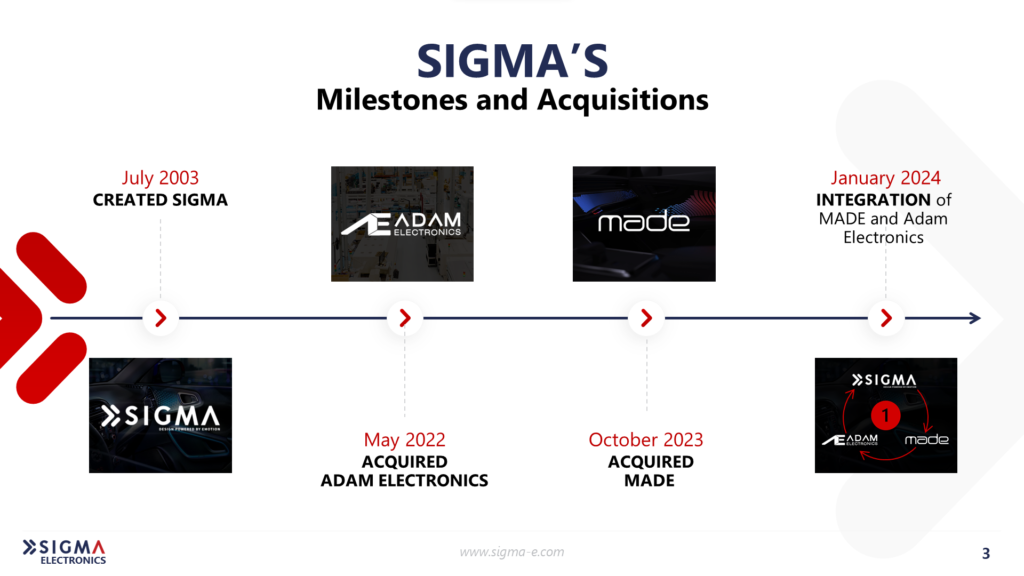

Our Journey

Three years of continuous growth and innovation

The Electronics We Manufacture Today Become the Technologies That Define Tomorrow

We are always looking for new projects and collaborations. If you have an idea or a project in mind, feel free to reach out to us.